La Crosse Corrugated Box Supplies

Nelson Container manufactures corrugated shipping boxes for businesses in La Crosse. Call us at 262-250-5000 for a quote and learn more about our packaging services.

Our Milwaukee area packaging facilities serves Western Wisconsin, La Crosse and the surrounding communities. Nelson Container manufactures ready-made corrugated packaging in less than 48 hours. Our speedy packaging services allow clients to respond quickly to changing product demands. Contact us today for corrugated products, customized to your business.

Ready Made Packaging in Less Than 48 Hours

Shipping Box Options

Whether you know the box dimensions you need and are looking for a manufacturer or just have the product and are looking for the best shipping solution, we are here to help. We are able to make any box to your custom dimensions to keep your products safe during shipping from your business to the destination.

Single Wall Boxes

Max suggested load 120 lbs. Edge Crush Test 26-55 Mullen 150# - 350#

Double Wall Boxes

Max suggested load 180 lbs. Edge Crush Test 48-82 Mullen 275# - 600#

Triple Wall Boxes

Max suggested load 300 lbs. Edge Crush Test 67-120 Mullen 700# - 1300#Where to Recycle Cardboard and

Corrugated Packaging in La Crosse, WI

D and M Recycling

841 2nd Ave SW, Onalaska, WI 54650

100% Recyclable Materials Used

Both our business and business models are 100% sustainable since both are based on efficiency. Our entire industry is based on recyclable materials, but so many companies are wasting time and space in their manufacturing process.

We employ quick response manufacturing (QRM) techniques, which add to the principles of just-in-time (JIT) and lean manufacturing, to achieve production exactly when you need it. No sooner. And definitely no later.

This technique helps to make Nelson Container as efficient as possible and reduce costs for the entire supply chain.

You can recycle corrugated board, but time lost is time wasted.

Engineered Corrugated Solutions Across Markets

At Nelson Container, we engineer custom corrugated solutions for every industry. From fragile electronics to heavy machinery, our packaging experts craft precision designs using single, double or triple wall construction with tailored fluting. Our in-house ISTA-certified lab rigorously tests each solution, subjecting prototypes to vibration, impact, drop and atmospheric conditioning trials. We use CAD technology and rapid prototyping to perfect designs quickly. Our flexible manufacturing cells are adaptable, providing same-day production and multiple daily deliveries.

Nelson Container engineers industry-specific corrugated solutions for every packaging challenge, safeguarding your products and optimizing your supply chain.

Our corrugated expertise drives value in your sector.

Switching to Nelson Container for

Packaging is Right for Your Business if:

- Your market or product is dynamic and demands Quick Response Manufacturing

- Easy, online ordering, eliminating POs, and reducing flubbed communications with eKban Online Ordering System

- Save significant sums of money, space, and time by reducing overhead costs and white space with Vendor Managed Inventory

Triple Wall Shipping Containers

Choosing heavy-duty shipping containers from Nelson Container is a worthwhile investment. Triple wall boxes are ideal for shipping, packaging and storage. Our corrugated containers are constructed with moisture-resistant adhesives and built to withstand the rigors of transportation. Triple wall boxes offer increased strength over typical containers while providing cushioning and insulating properties.

Custom Engineered Packaging Solutions

Fact—Nelson Container reduces lead times and improves turnaround times for your business.

Fact—you’ll be able to meet your clients’ needs in a more timely manner when you partner with Nelson Container for your high-value, volatile product packaging requirements.

Learn more about our corrugated packaging options:

Single Wall Boxes Double Wall Boxes Triple Wall Boxes

Don’t just wait around for shipping solutions to hit you on the head. Think outside the box. Think Nelson Container for your dynamic shipping needs.

Learn Why We're Better Custom Package Design Contact Nelson Container

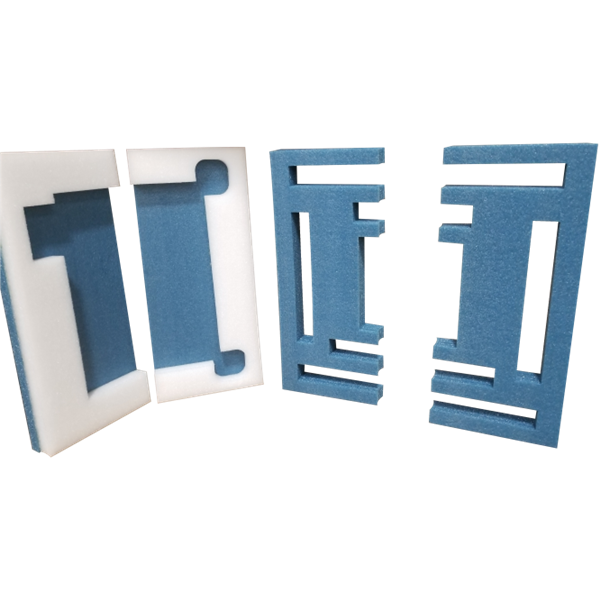

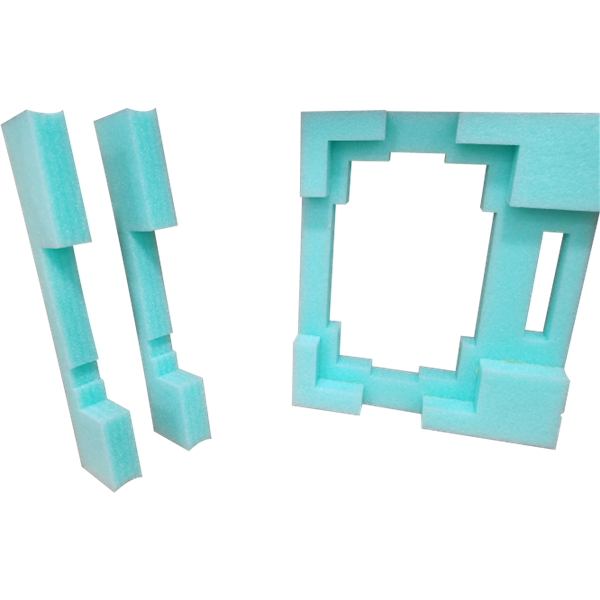

Inner Foam Packaging Protects Your Products

At Nelson Container we offer a number of protective foam packaging options to keep your products safe. The type of foam used in your packaging depends on what you are looking to ship. Convoluted (egg crate) is great for keeping fragile products safe during transit due to its shock absorption properties. Another common type of foam inserts is anti static foam, primarily in shipping sensitive electronic products to provide added protection while mitigating the risk of static electricity causing damage to the electrical components.

Close Proximity to La Crosse Businesses

Nelson Container’s plant in Germantown is just across Wisconsin from La Crosse if there’s traffic. The close proximity of Nelson Container to you, a possible business partner, is a major benefit. With less space between us and you, there’s proportionally less risk of anything deterring you from reaching your business goals.

The short distance also helps to reduce lead times and calms any scenes of bedlam your warehouse may resemble. Once you have your packaging, your products can finally leave your warehouse, freeing up space for you to take on new projects and conquer new markets, which is where we were going next...

24-Hour Turnaround Times

We get your packaging to you fast. Our business day starts at 4 in the morning, allowing us to get your order, process the specifications, set up our machines, and completely manufacture your packaging almost as soon as you thought to order it. That’s fast.

Starting our business day early means we can schedule more ship-out times, and have orders arrive at your business’ door before tomorrow is through. Our drivers are always safe, both on the road and in receiving areas. You’re not going to have to wait an extra day because a driver got in a collision. After all, transportation is a large part of reliable shipping solutions.

Vendor Managed Inventory (VMI)

Vendor managed inventory does not mean we keep track of how many Snicker's bars you have left in your vending machines. We don't keep track of everything in your inventory; only the things we need to be aware of in order to get your packaging to you at the right time.

When is the right time? When your products are done being produced. If you don't get those things out of your warehouse right away, they're only taking up space that could be used for other inventory.

VMI is an essential part of our quick response manufacturing system, which we've enacted throughout our entire business and extended to those businesses with whom we partner. If Nelson Container isn't able to schedule our manufacturing in cooperation with our partners', the system works less efficiently, slowing turnaround times and lowering bottom lines.

QRM and Nelson Container Help You:

- Reduce overhead costs

- Clear space in your warehouse

- Reduce your impact on the environment

- Almost eliminate lead times

Quick response manufacturing (QRM) is great for your business as well as ours.

The Beast Builds

the Best Corrugated Boxes

Our largest box making machine, a jumbo folder/gluer, allows us to create bulk corrugated boxes of any size faster and cheaper than anyone else in Southeast Wisconsin. Newly designed packages have a lead time of 48 hours and repeat packages are down to an astounding 24 hours.

Each corrugated box order is made to your exact specifications. We are able to use whatever types and grades of materials you need, with either stitched or glued joints to package your products.

Pre-Assembled Packaging

Nelson Container has workers who specialize in assembling your packaging before it arrives at your warehouse or production room floor. When your packaging is complicated, requires taking the time to fold and insert one piece into another, or just isn't something you want to have your workers assemble, we do it for you.

Pre-assembling your packages saves you time and money. Your workers can continue working on what they do. We continue to work on creating the fastest and best packaging available. And the rest of the supply chain continues doing what they do best—supplying.

Difference Between

Corrugated Packaging and Cardboard Boxes

"Cardboard" is used to refer to any kind of flat paper packaging. Most of the time people say cardboard when they mean corrugated. Corrugated can be identified by the unique "fluting" between flat layers which gives the packaging slightly more volume while offering much more support. You're probably looking for corrugated, not cardboard.

Contact Nelson Container, and partner with a reliable packaging manufacturer.